Why Custom Copper Range Hoods Beat Wood and Mass-Produced Alternatives: 5 Reasons That Matter

Posted by Marc, CopperHoods.com Master Designer on Oct 6th 2025

Well, hello there, kitchen maestro! Marc here, and after over a decade of designing custom copper range hoods that make neighbors say "Well, would you look at that!"—I figured it was high time we had a heart-to-heart about why copper beats the competition faster than you can say "dinner's ready."

Now, I've seen every material and approach under the sun try to muscle its way into kitchens across America. Wood range hoods, mass-produced cookie-cutter options, even those unfortunate over-the-range microwaves trying to masquerade as ventilation—you name it, I've watched homeowners wrestle with disappointing alternatives. But here's the thing: there's a reason we've been the go-to choice for discerning homeowners and design professionals since 2013, and it's not just our commitment to quality craftsmanship (though that doesn't hurt).

So grab a cup of coffee—strong, the way we like it—and let me walk you through the 5 material and construction reasons why choosing a custom copper range hood from CopperHoods is the smartest decision you'll make for your kitchen.

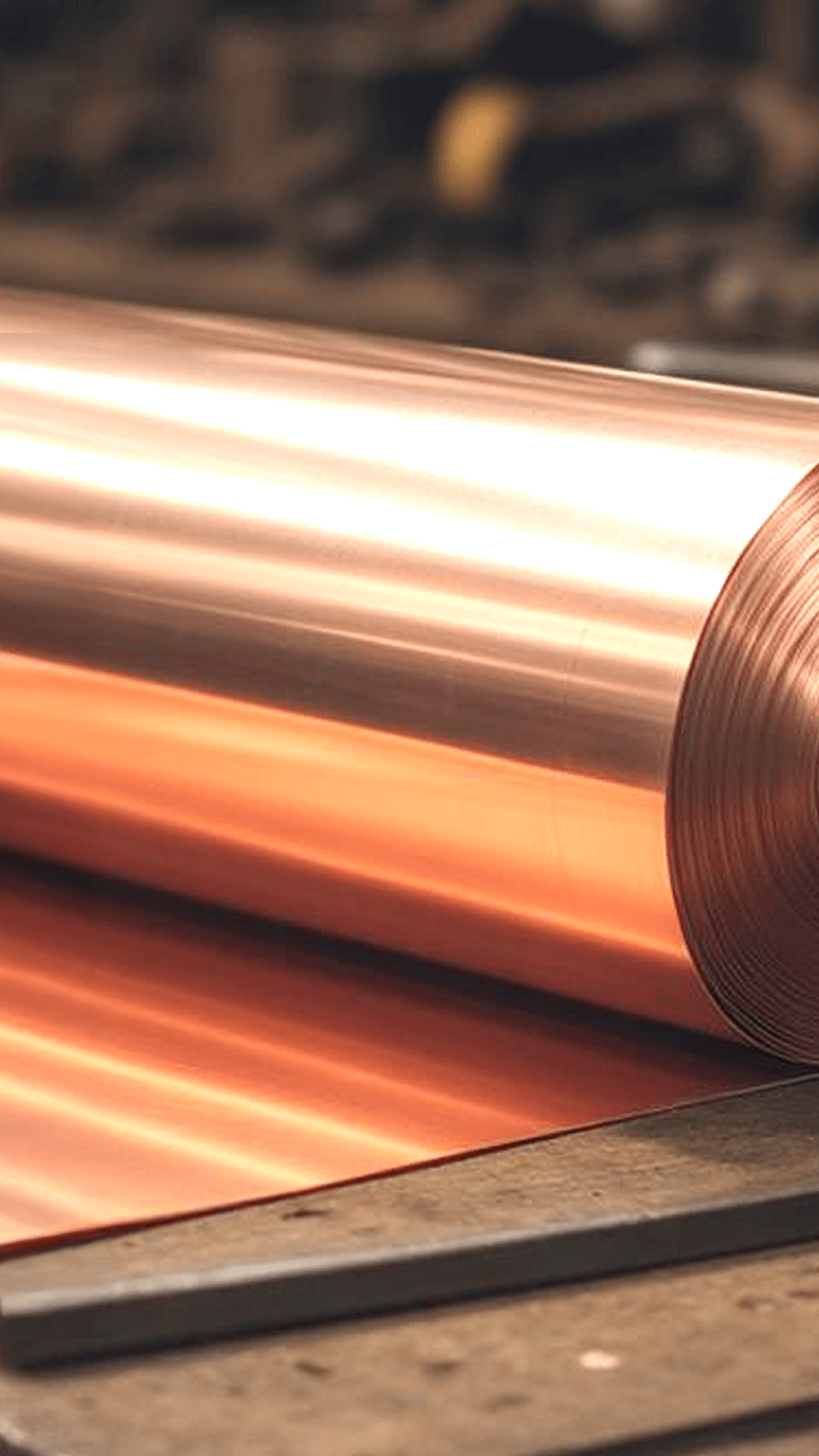

1. Pure, Cold-Rolled 16-Gauge Copper That Laughs at Imitation

Let's start with the star of the show: our copper. While competitors cut corners with thin, flimsy materials, we use pure, cold-rolled 16-gauge copper that's built to last generations. This isn't your garden-variety copper sheet—this is the real deal, meticulously selected for its strength, durability, and stunning natural beauty.

Wood range hoods? They warp, crack, and collect grease like a sponge collects water. One season of humidity changes and you're looking at gaps, splits, and maintenance headaches. The porous nature of wood means grease seeps in and becomes nearly impossible to clean thoroughly.

Mass-produced hoods? They're stamped out with the thinnest gauge metal manufacturers can get away with—often 20-gauge or thinner. That means dents, dings, and a flimsy feel that screams "cheap" the moment you touch it.

Over-the-range microwaves? Let's not even pretend these are real ventilation solutions. They're appliances with a fan bolted underneath, recirculating your cooking odors back into your kitchen. No craftsmanship, no style, no actual venting power.

Our copper is a living metal that only gets more gorgeous with age – kind of like a fine wine, but for your kitchen. Each custom copper range hood becomes more unique and characterful as the years roll by, creating a living centerpiece that tells your family's story.

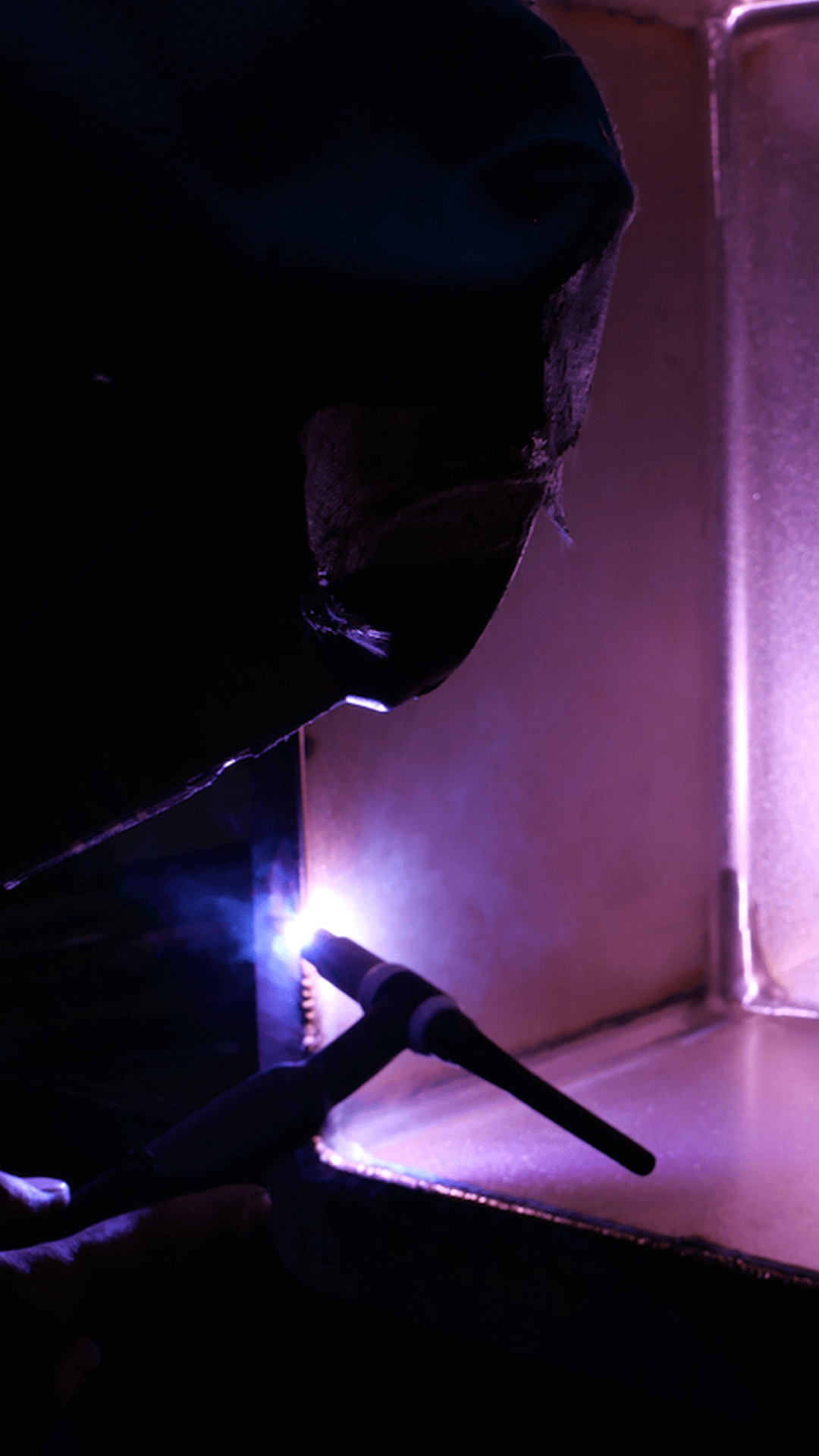

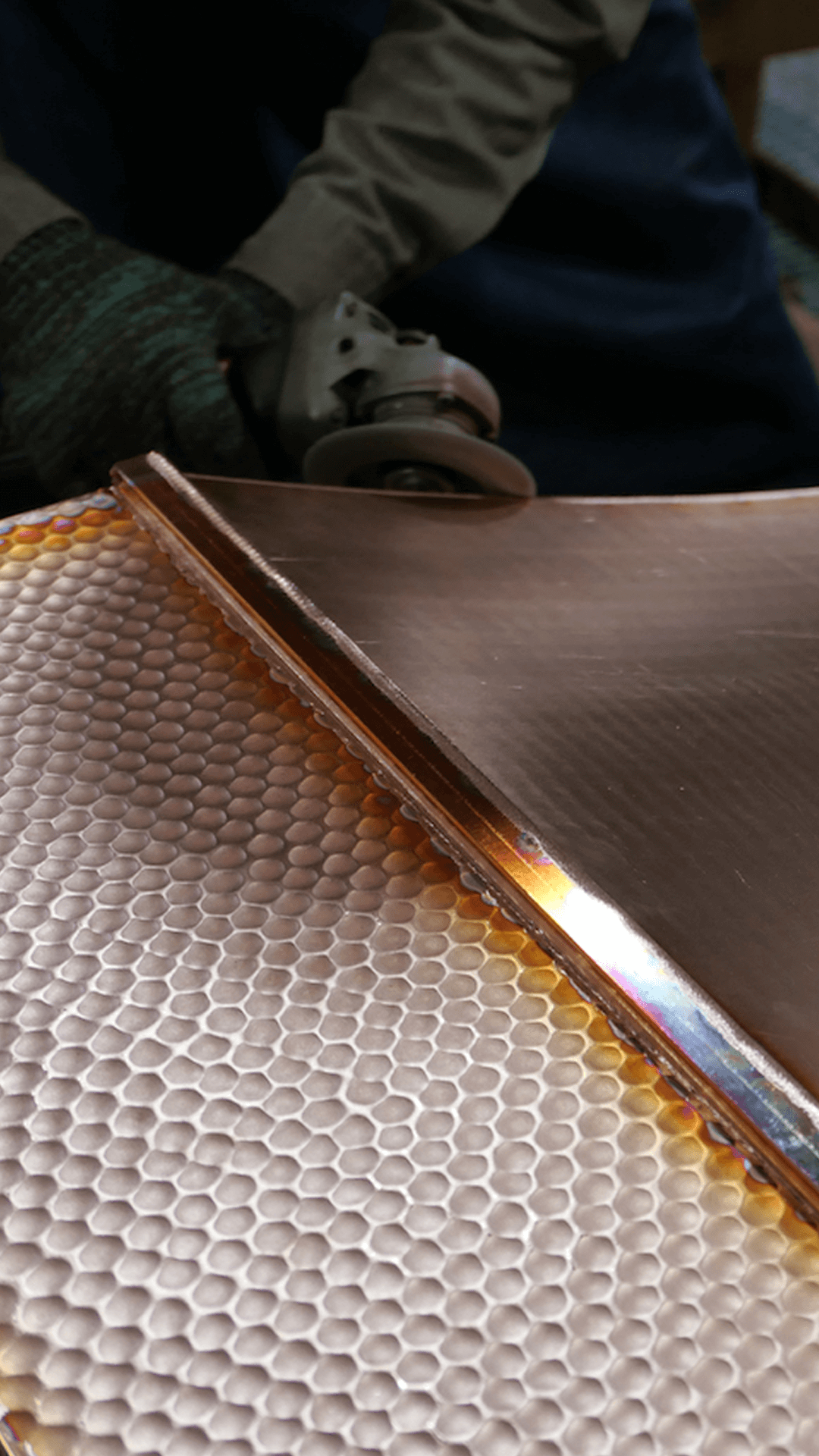

2. TIG Welding Stronger Than Grandma's Grip on a Secret Recipe

Here's where we separate the wheat from the chaff, folks. Our TIG welding technique creates bonds with the highest tensile strength in the game. While other manufacturers of kitchen range hoods use cheaper welding methods that can fail over time, our welds flex and hold like they're part of the original copper sheet.

Why does this matter? Because your range hood isn't just hanging there looking pretty—it's working hard every day. Temperature changes, vibrations from your exhaust system, the weight of the copper itself—all of these forces are constantly at play.

Wood hoods? They're held together with screws, nails, and glue that can loosen, rust, or fail. Every joint is a potential weak point. After a few years of kitchen heat and humidity, those connections start to give way.

Mass-produced hoods? They use spot welding or cheap rivets that create weak points throughout the structure. When (not if) these fail, you're looking at rattling, separation, or complete structural failure.

Our TIG welding ensures your investment stays secure and stunning for generations to come. It's the difference between a handcrafted range hood and a mass-produced liability waiting to happen.

3. Customization Options NOT that Mass-Produced Look

Cookie-cutter options from big box stores? Please. We're talking about over 50 colors and textures, four distinct hood styles (Curved hoods, Bell Shaped hoods, Box hoods, and Pyramid hoods), and endless customization options including straps, rivets, bars, and custom aprons.

Want a Duluth-style copper kitchen hood with brass patina and decorative straps? Done. Prefer a sleek Minneapolis design with a hammered finish? You got it. Every CopperHood is as unique as your secret family recipe—and twice as impressive. Here's what you can customize on your artisan range hood:

- Hood Style: Curved, Bell Shaped, Box, or Pyramid

- Finish Options: 50+ colors and textures from natural copper to aged brass

- Decorative Elements: Straps, rivets, and bars (all included—no upcharges!)

- Apron Design: Clipped, straight, arched, or custom profiles

- Size & Dimensions: Built precisely for your kitchen layout

- Material Choice: We also craft stunning stainless steel range hoods for those who prefer a different aesthetic

Compare this to:

- Wood range hoods: Maybe 3-4 standard stain colors, minimal design variation

- Mass-produced hoods: Pick from 2-3 predetermined sizes and finishes – that's it

- Big box options: "Customization" means choosing between small, medium, or large

With CopperHoods, you're not adapting your kitchen to a product—we're adapting our product to your vision. Your kitchen deserves better than whatever happens to be in stock at the warehouse.

4. A Structural Warranty That Means Something

Let me ask you this: when's the last time you saw a wood range hood company offer a lifetime structural warranty? We stand behind our work like an iron skillet stands by its seasoning – for life. This isn't marketing fluff; it's a promise backed by over a decade of proven craftsmanship. When you choose a custom copper range hood from CopperHoods, you're not just buying a kitchen hood; you're investing in a family heirloom.

What does our lifetime warranty cover?

- Structural integrity of all TIG welds

- Material quality and copper thickness

- Manufacturing defects in workmanship

- Coating adhesion and performance

Wood hoods typically offer 1-2 year warranties, if any. Why? Because manufacturers know wood warps, cracks, and deteriorates. They can't stand behind a material that's fundamentally unsuited for the harsh kitchen environment.

Mass-produced hoods might offer 5-10 years, but with plenty of exclusions for normal wear and tear. Read the fine print and you'll find that almost nothing is actually covered.

Over-the-range microwaves? Sure, the microwave might have a warranty, but the ventilation components? Good luck. These aren't built to be permanent fixtures – they're appliances designed for eventual replacement.

We've been crafting handcrafted range hoods since 2013, and we've seen our early installations still looking stunning today. That's the confidence that comes from using premium materials and time-honored techniques.

5. Baked-On Clear Coating That Battles Oxidation

Wood finishes fade, chip, and require constant maintenance. Cheap copper hoods oxidize and turn green faster than you can say "Statue of Liberty." Our proprietary baked-on clear coating is oxidation resistant and tougher than determination itself, protecting your investment while maintaining that gorgeous copper glow. This beauty treatment isn't just skin deep—it's engineered to withstand:

- Kitchen Heat: Constant exposure to cooking temperatures

- Humidity: Steam, moisture, and everyday cooking conditions

- Daily Use: Cleaning, touching, and general kitchen activity

- Time: Years of service while looking like installation day

Let's talk about what happens to the competition:

Wood range hoods require regular oiling, refinishing, and maintenance. Miss a maintenance cycle and you're looking at dried-out, cracked, or discolored wood. The grease buildup alone can stain wood permanently, and that porous surface is a bacteria magnet.

Mass-produced hoods typically use powder coating or cheap paint finishes that chip, fade, or peel within a few years. Once that protective layer is compromised, you're dealing with rust, corrosion, and deterioration.

Uncoated copper develops a green patina (which some people love, admittedly), but if you want to maintain that warm copper glow, you're in for a lifetime of polishing and chemical treatments.

Our baked-on clear coating keeps your copper kitchen hood looking pristine with nothing more than a gentle wipe-down. It's the perfect balance of protection and beauty—set it and forget it.

The CopperHoods Material Advantage:

Built to Last, Designed to Impress

Look, I could go on for days about the technical superiority of custom copper over mass-produced alternatives, the craftsmanship advantages we offer over wood options, or the way our hoods age gracefully while cheaper alternatives fade into oblivion. But here's what it really comes down to:

We use pure, cold-rolled 16-gauge copper, brass, or 304 stainless steel that's built for the long haul. We weld it with TIG precision that creates bonds stronger than the original material. We protect it with an oxidation-resistant coating that keeps it beautiful for life. We back it with a lifetime structural warranty because we know it'll outlast your kitchen (and probably your house). And we give you unlimited customization because your kitchen deserves more than off-the-shelf mediocrity. Why copper wins:

- Durability: Won't warp, crack, or deteriorate like wood

- Beauty: Develops character over time instead of showing wear

- Value: One-time investment vs. repeated replacements

- Customization: Endless options vs. limited mass-produced choices

- Craftsmanship: Hand-forged by skilled artisans vs. stamped by machines

When you choose a custom copper range hood from CopperHoods, you're not just buying superior materials— you're investing in a centerpiece that will make people stop in their tracks and say, "Now THAT'S what I call a kitchen!"

Ready to see how your custom copper range hood will look? Try our revolutionary 3D Hood Builder at CopperHoods.com and watch your vision come to life in photo-realistic 3D. Pick your style, choose your finish, and add your custom details—all while getting an instant price quote.

Stay tuned for Part 2, where I'll share 5 more reasons why CopperHoods outshines the competition—including how we deliver value, provide exceptional service, and create a customer experience that'll make you feel like family.

Marc

Master Designer, CopperHoods

"Crafting culinary centerpieces with a spark of brilliance"

Ready to transform your kitchen with a custom copper centerpiece? Get your hassle-free quote today at CopperHoods.com—because every kitchen deserves to be the envy of the neighborhood.